A1400/A1700 8488-1A fluid end soutwest for mud pump

Delivery time 1-2weeks

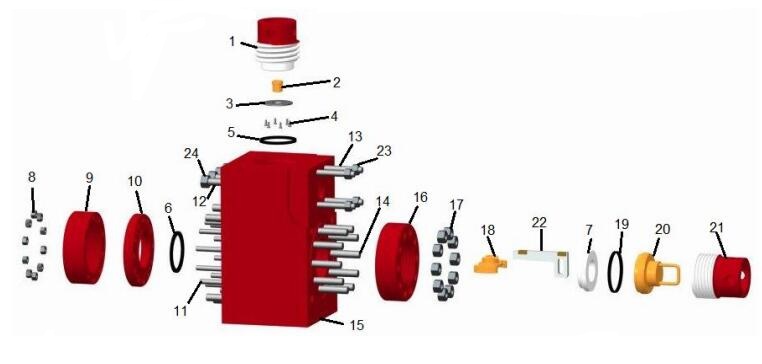

The fluid end mainly cons sts of cylinder block, liner, piston, valve, suction manif old, di schargemanifold, discharge pulsation dampener, relief valve and spray ing device etc For detai Is,

Cylinder block

The suction chamber and discharge chamber are integrated in a vertica cylinder block(according toA DC, Over Under Valves front-loading). The valve pot struct ure and dimens ons meet API 7KSpecif icai ons. T he cylinder blocks are fixed on the frame thr ough bolts

Liner

he drill ing pump adopts bimetallic liner. Liners with different diameters can be selected according todi fferent drilling conditions. The liner is fixed on cylinder bl ock with bolts through liner thread ring andiner lock. The liner and piston and piston rod can be lift and put in or taken out from the opening on the topof frame with the help of sm all lifting device mounted on frame

Piston

The piston consists of piston core, pi ston rubber, clamping bar, circlip. T he piston rod is connectedto extension rod through clamp, the piston and piston rod are connected by piston nut

Liner spraying device

liner spraying device is consisted of spray pump, water tank, spr aying mani fold etc. Its function is tow ash, lubricate and cool liner and piston during mud pump running in order to prolong the service life ofner and pist on. T he spraying pipe positi on is shown in Fig